|

Breather mesh is plastic fabric used inside a vacuum bag that allows air to flow away from the project being pressed and towards the vacuum port (also called the "bag stem"). It is used in place of a top platen. Breather mesh is plastic fabric used inside a vacuum bag that allows air to flow away from the project being pressed and towards the vacuum port (also called the "bag stem"). It is used in place of a top platen.

Without breather mesh, vacuum bag material will seal against itself or against the veneer panel causing pockets of reduced vacuum. These pockets of insufficient vacuum do not have the clamping force needed to adequately press the veneer down onto the substrate. Breather mesh helps create evenly-distributed vacuum/force inside the bag and this is the key to successful vacuum pressing.

A bottom platen (typically 3/4" melamine board) is still required when breather mesh is used, but there is no need to cut grooves in it. To be very clear about this, only a single 3/4" melamine board without grooves is needed if you are using breather mesh. The platen board must be as large as your project panel, but it can be larger. Some users prefer to have one platen board sized to fit their bag, and they use that same set up for all projects large and small.

The bottom platen is only used to provide a flat reference surface which helps to keep the veneer panel from warping while the veneer adhesive is setting up. The mesh acts as the top platen. It helps create even distribution of vacuum and it presses most veneers down firmly against the substrate while the glue sets up.

Breather Mesh Advantages

- Light weight

- Inexpensive

- Re-usable

- Allows you to see the veneer as it is being pressed

|

- Does not fatigue the bag material

- Reduces bleed-through artifacts

- Easy to use, cut, and store

- Will not stick to most veneer adhesives

|

An Ounce of Prevention

The life of the vacuum bag and the mesh can be significantly increased by easing all of the platen board edges with a 1/4" or 3/8" radius round-over router bit.

|

Saw Horses

Some users set their vacuum bag and platen board over a pair of saw horses. This can be problematic since the platen board can bend under its own weight. It is better to place the vacuum bag and platen on a flat work bench surface instead. |

Window Screen Material As Breather Mesh

Window screen material can create a pathway for the flow of vacuum to the bag stem. Several users have sent me messages saying they had no issues other than a moderate increase in the amount of time it took to draw full vacuum in the bag. It is important to know that a veneer that is not completely flat is not likely to flatten directly under window screen material; you can get lumps in the finished panel.

The other issue is that any adhesive that bleeds through the veneer will smear back onto the surface of the panel. The breather mesh offered at VeneerSupplies.com has a wider and more open weave than screen material so glue that comes through the veneer beads up and can be easily scraped off. I've also found that breather mesh is much easier to slide into the vacuum bag than screen material. |

Veneer Placement When Breather Mesh Is Used

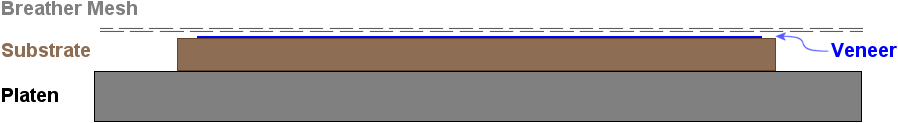

| Scenario 1 |

|

Application: |

Applying the Face and Balance Veneers One at a Time |

Veneer: |

The veneer must be completely flat. |

Substrate: |

The substrate is the same size or larger than the veneer. |

Process: |

Since all panels must have a veneer on both sides, start by applying the balance veneer. This will provide a sense of whether or not too much glue is being applied. It's better to learn this from the balance veneer than the expensive show veneer. When the balance veneer is finished in the press, immediately work to apply the face veneer in the same manner. |

Trimming: |

The substrate will be trimmed to size after pressing is complete. |

Bleed-Through: |

This setup makes it easy to remove glue bleed-through. |

Notes: |

This method is often the best and easiest way to veneer a panel.

You can use clean-release tape to hold the veneer in place.

|

click to enlarge

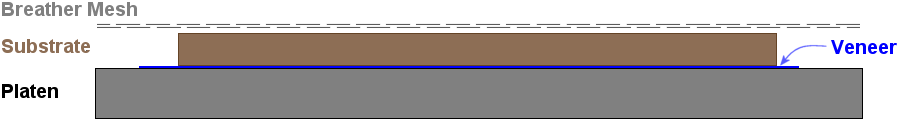

| Scenario 2 |

|

Application: |

Applying a Veneer When Extra Force is Required |

Veneer: |

This is used when the veneer is mostly, but not completely flat . |

Substrate: |

The substrate is the same size or smaller than the veneer. |

Process: |

Since all panels must have a veneer on both sides, start by applying the balance veneer. This will provide a sense of whether or not too much glue is being applied. It's better to learn this from the balance veneer than the expensive show veneer. When the balance veneer is finished in the press, immediately work to apply the face veneer in the same manner. |

Trimming: |

The veneer will will be trimmed to size with a down-cutting spiral router bit or veneer saw after the pressing is complete. |

Bleed-Through: |

Be sure to avoid excessive veneer glue with this method because bleed-through can cause splotching on the veneer face. |

Notes: |

In this case, the substrate acts as a platen to put additional clamping force on veneers that are not completely flat. Very wavy veneers must first be flattened with veneer softener. |

click to enlarge

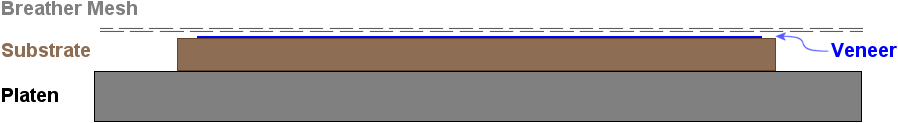

| Scenario 3 |

|

Application: |

Applying the Face and Balance Veneers at the Same Time |

Veneer: |

The show veneer is completely flat and the balance veneer is completely or mostly flat. |

Substrate: |

The substrate is the same size or larger than the veneer. |

Process: |

The face veneer and balance veneer are applied simultaneously. |

Trimming: |

The substrate will be trimmed to size after pressing is complete. |

Bleed-Through: |

This position makes it easy to remove glue bleed-through on the show veneer side of the panel. The balance veneer may not be visible on some projects, so bleed-through is often not a concern. |

Notes: |

This tends to be the fastest way to complete a panel, but you must work quickly to apply the veneer glue and set the veneer on both sides of the panel. You can use clean-release tape to hold the veneer in place. |

click to enlarge click to enlarge

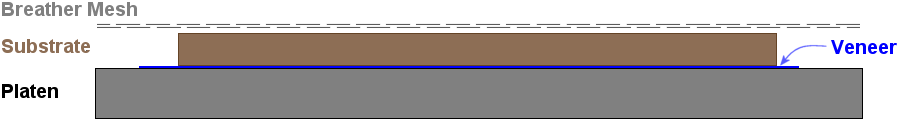

| Scenario 4 |

|

Application: |

Applying a Veneer When Extra Force is Required |

Veneer: |

Both the show veneer and the balance veneer are mostly flat.

This method is often used if both veneers are thicker than normal.

|

Substrate: |

The substrate the same size or larger than the veneer. |

Process: |

The face veneer and balance veneer are applied simultaneously. |

Trimming: |

The substrate will be trimmed to size after pressing is complete. |

Bleed-Through: |

Be sure to avoid excessive veneer glue with this method because bleed-through can cause splotching on both veneers. |

Notes: |

The top platen helps put additional clamping force on veneers that are not completely flat or very thick. It's strange how this works, but you will get the effect of more downward force on the top veneer if a top platen is used. The top platen does not have to be 3/4" thick. If you can find 1/4" melamine board, then it will work just as well.

Keep in mind that very wavy veneers must first be flattened with veneer softener. |

click to enlarge

The Ideal Set-Up for Most Flat Panels

If you have a small project to veneer, you may not be using the full width or length of the vacuum bag. In this case, insert a platen and place your veneer and glued-up substrate on top. Then place the breather mesh over the entire veneer surface leaving a few inches of over-hang at the edge closest to the bag stem. Position the entire assembly so that the bag stem is above the overhanging breather mesh. This will allow you to evenly distribute vacuum over the veneered panel.

Note that the breather mesh and bottom platen

must be larger than the project panel.

Optional Vacuum Mesh Bridging

If your breather mesh is large enough to only cover the project and if you want to keep the bag stem off the veneered panel, you can cut a small strip of breather mesh from any over-hanging side and place it between the main part of the mesh and the bag stem. The "bridge" piece should lay on top of the mesh that covers the project. I've done this with a strip that was only 2" x 12". This bridges the main mesh to the bag stem. Think of it as a pathway that allows air to move out of the bag.

Keep in mind that the vacuum bags offered at VeneerSupplies.com have a flush-mount stem. In other words, the bottom of the stem does not protrude into the bag. This means you can put the bag stem right on top of the mesh and directly over the veneer. That's why this section is titled "optional".

A breather mesh "bridge" makes a pathway

for air flow to the bag stem.

Breather mesh can have sharp edges. Some readers have suggested covering the edges of the breather mesh with duct tape. |

Breather mesh is typically cut to fit the size of the vacuum bag if most of the user's projects will be flat panels, but curved projects often require a piece of mesh cut to match the panel size. |

Bleed-Through Issues Made Easy

When vacuum is applied to the veneer, burl veneers will sometimes allow small amounts of glue to pull through the veneer face. This is often referred to as "bleed-through" and it can be a challenge to remove. With the old-school dual platen setup, the glue that bled through to the face of the veneer was forced to spread out on the surface and created a splotching effect.

However, with breather mesh the glue stays in a tight bead on the surface of the veneer which is easily sanded or scraped off with a minimal amount of effort. After the excess adhesive is removed, the only glue on the face will be that which has filled any voids in the veneer. This is a great advantage and will give you a smoother finished panel.

The key to preventing bleed-through is to use the right amount of adhesive with a dedicated veneer glue roller. The surface should be completely and evenly coated with the veneer adhesive. When applied correctly, you should be able to see the substrate through the wet glue layer.

To make this as easy as possible, I often draw a few pencil lines on the substrate before applying the glue. Then I use the roller to spread to glue out so I can readily see the pencil lines through the glue layer. At that point, I know I've probably used the right amount of glue. Even with the correct amount of adhesive, some bleed-through is possible. This is especially true with burl veneers and open-pore species like ash and oak.

Bleed-through with a platen or caul |

Bleed-through with breather mesh |

- Keep in mind that you can veneer the back side of the substrate at the same time as the face veneer as shown in scenario 2 above. With this method, breather mesh is not used on the back side of the panel since the platen will prevent any air pockets from forming.

- Non-flat veneers over 1/32" in thickness may not flex enough to perfectly mate with the substrate surface when breather mesh is used directly above it. In this case, a 1/2" or 3/4" thick top platen is often a better choice. See scenario #4 above for a diagram of this set up. You must cut grooves in the top platen as shown on this page or just use breather mesh over the top platen instead.

- Breather mesh may leave small impressions in softer woods such as walnut, redwood, and pine which can typically be sanded off. Reducing the vacuum level can help. A clothes iron can sometimes be used to raise any impressions left by the mesh. Lightly spritz the veneer face with water (after the glue is fully cured) and then iron lightly. Be sure to place a piece of cotton or flannel over the veneer surface to prevent scorching.

Breather mesh used to make a half-cylinder.

|

Breather mesh

Breather mesh

click to enlarge

click to enlarge